Managing cash flow, planning the financial outlay, keeping the balance sheet in order, and ensuring all financial compliances are met are a CFO’s core job function. But this is not all that a CFO does. The CFO is also responsible for identifying opportunities to reduce operating costs without sacrificing the quality of the products and services offered by the company.

But is it a good strategy to wait for things to go wrong to ask the CFO to step in?

Supply chain and transportation are two of the biggest cost centers in an organization. The cost for these functions is measured as a percentage of sales and differs from industry to industry. However, according to this McKinsey study, most industries report supply chain and logistics cost in the range of 1.8% to 10%. When costs remain within the industry parameters, supply chain and logistics are usually given the leeway to make their financial decisions. The CFO steps in only when the cost rise above the set industry norms or in case any other financial abnormality is noticed. But is it a good strategy to wait for things to go wrong to ask the CFO to step in? Wouldn’t the supply chain and the organization as a whole benefit if the CFO is a part of the supply chain decision making?

What Does the Corporate World Think of CFO’s Involvement in the Supply Chain?

The necessity of CFOs involvement in supply chain is not a recent phenomenon. A 2013 study by Ernst & Young aptly highlighted the importance of CFO’s involvement in the supply chain. Ernst & Young surveyed 423 CFOs and heads of supply chain around the globe to understand their view of a CFO’s contribution to the supply chain.

According to the results of the survey, of all the respondents, “only 26% finance executives and 21% supply chain executives said that the CFO’s contribution to the supply chain is based around a business-partnering model”. But this trend seems to be gradually changing as “70% of CFOs and 63% of supply chain leaders responded that their relationship has become more collaborative over the past three years”.

Organizations that have a collaborative relationship between the CFO and supply chain also tend to perform better.

The survey also revealed that those organizations that have a collaborative relationship between the CFO and supply chain also tend to perform better. “Among survey respondents with an established business partner model in place, 48% report EBITDA growth increases of more than 5% in their company over the past year, compared with just 22% of those that have not yet adopted this approach.”

In the past five years, the demand for CFO’s involvement in the supply chain has only grown. Last year, an article in the European Financial Review spoke about the book What CFOs (and Future CFOs) Need to Know About Supply Chain Transactions by X. Paul Humbert, Esq. According to the article, the book showcases not only the necessity of a collaboration between the CFO and the supply chain but also demonstrates how the company’s finances and its books are impacted by the decisions taken by functions within the supply chain:

“an organization’s financial results are intertwined with the performance of the purchasing function. Purchasing and purchased inventory affect the balance sheet and capital allocation.”

Another article in Smart Industry Update published in 2018, speaks on behalf of the CFOs seeking answers to supply chain issues which the CFOs may not have first-hand knowledge of. For example, the article lists the following three critical questions that CFOs should ask of their supply chain to be able to make better decisions regarding their supply chain and create better business strategies:

- How accurate is our supply-chain visibility?

- How quickly can we identify and address challenges in response to disruption?

- How well can we respond to changes in the industry?

The survey and the two articles leave no doubt of how crucial it is for CFOs to be involved in the supply chain function and work in collaboration with the head of supply chain. In fact, it is not only the supply chain that needs the CFO, the CFO also needs the supply chain.

How The CFO Can Be A Change Agent For The Supply Chain

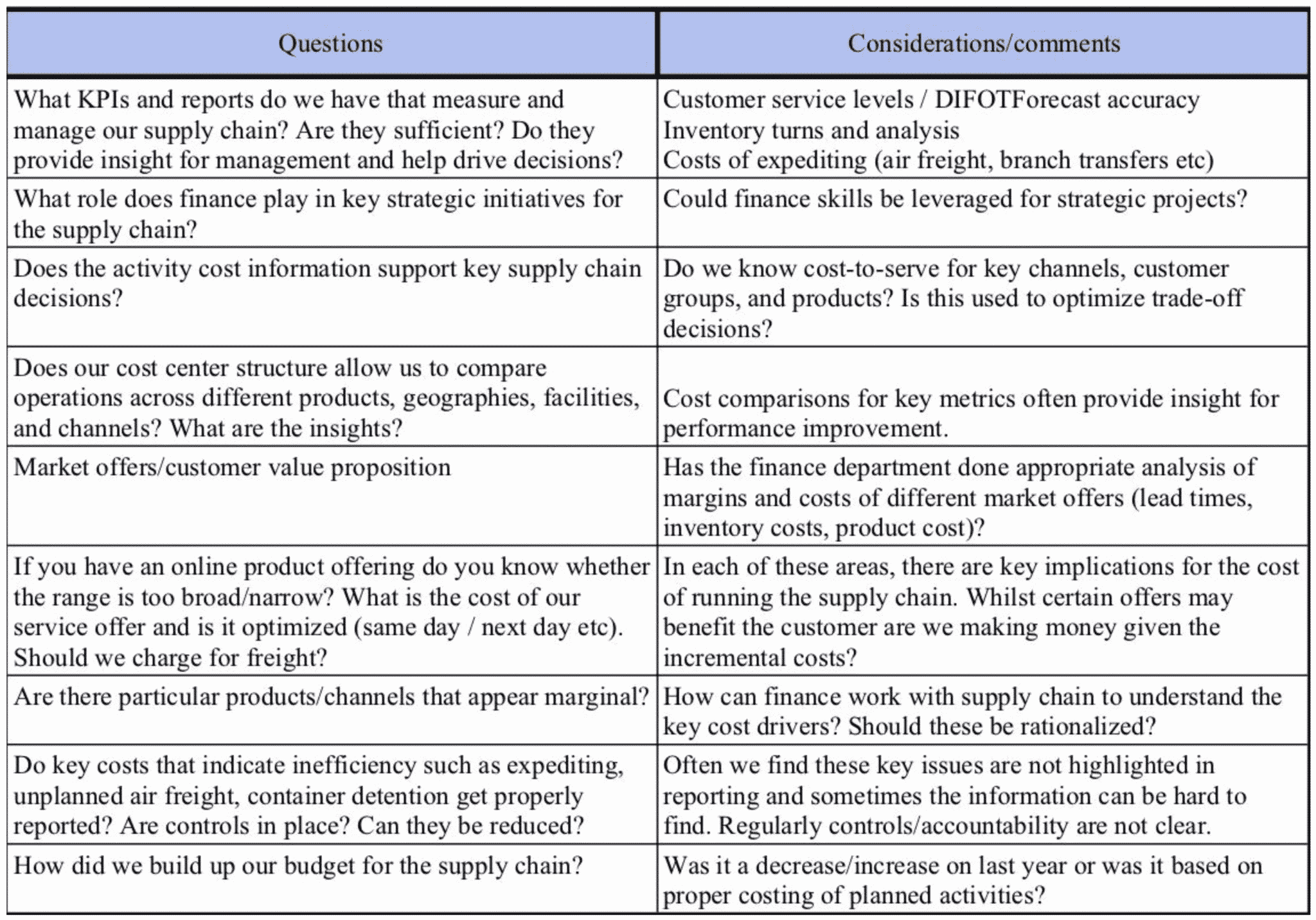

An article titled How Brilliant CFOs Use the Supply Chain to Drive Business Value – Do you know the questions you should be asking in Innovation Enterprise targeted at CFOs lists down possible areas that can benefit from the CFO’s involvement.

It says “If the answer to any of these questions highlights a potential issue then it is important to engage with the head of supply chain and agree a process to address the issue. It may also indicate that there is an opportunity to partner more closely with supply chain/operations to leverage the knowledge and skills of the finance team to enable better decision making in the business.”

The transportation offered also influences customer’s buying decisions

All the above areas are crucial from the financial, product, and delivery point and can benefit from a collaborative effort from the CFO and the supply chain. For example, let’s take a look at the second, sixth and eighth question. Freight costs are pegged around 3 – 5% of supply chain costs. Freight contract negotiation is one of the most important activities of the logistics function. It has an impact on the budget, affects the cost reduction KPI given to the logistics department. In B2C businesses, to a certain extent, the transportation offered also influences customer’s buying decisions. How can the function benefit from CFOs insight?

When the CFO is involved in this decision-making from the start, it increases the possibility of improvement in contract terms and in cost reduction.

On the cost reduction and financial front, the CFO, with their fact-based view of the organization, can help the logistics team negotiate better freight contracts. The rates negotiated in these contracts are based on a multitude of factors like government policies, fuel prices, political relations between trading countries, and global business environment. Logistics may or may not have insight into these issues, but the CFO and his team will have knowledge of what is going on in the business world. So, if they know there is a possibility of fuel prices changing in the next six months or a recessionary trend is being noticed, they can advise the logistics team to negotiate a short-term contract and revisit it later. Similarly, in the case of B2C shipments (ref Q6), the CFO and the supply chain head can negotiate for contracts with different delivery options in order to serve different customers. But this can only be done if the supply chain knows the financial viability of these options and that information can be gained only from the CFO of the organization. When the CFO is involved in this decision-making from the start, it increases the possibility of improvement in contract terms and in cost reduction.

Today, to be effective in their job and to create a competitive supply chain, CFOs need to lend their expertise to the supply chain and seek their inputs in the setting the goals and objectives of the company.

Long gone are the days when the CFOs limited themselves to matters pertaining to managing company finances. Today, to be effective in their job and to create a competitive supply chain, CFOs need to lend their expertise to the supply chain and seek their inputs in the setting the goals and objectives of the company.

At BlueGrace, we have found that working with organizations where CFOs are directly involved has helped turn over a new leaf and make significant cost reductions, positively impacting the supply chain of that organization.

We provide quarterly business intelligence reports that give updates on the savings targets you give to us, key performance indicators (KPIs), and special project updates. The CFO of a company, in particular, is able to use these metrics to budget and forecast for the organization moving forward. Connect with our team at 800.MY.SHIPPING or fill out the form below to find out how we can work with your CFO to build an efficient and optimal supply chain.